Thru-Hole vs. Threaded Hole vs. Pintop Balusters

Choosing the right baluster installation method is key to ensuring your staircase is secure, quiet, and visually clean. While material plays a role, it's the connection points—top and bottom—that truly affect long-term performance. Below are three of the most common installation methods used for metal stair balusters, each with its own strengths, challenges, and ideal applications.

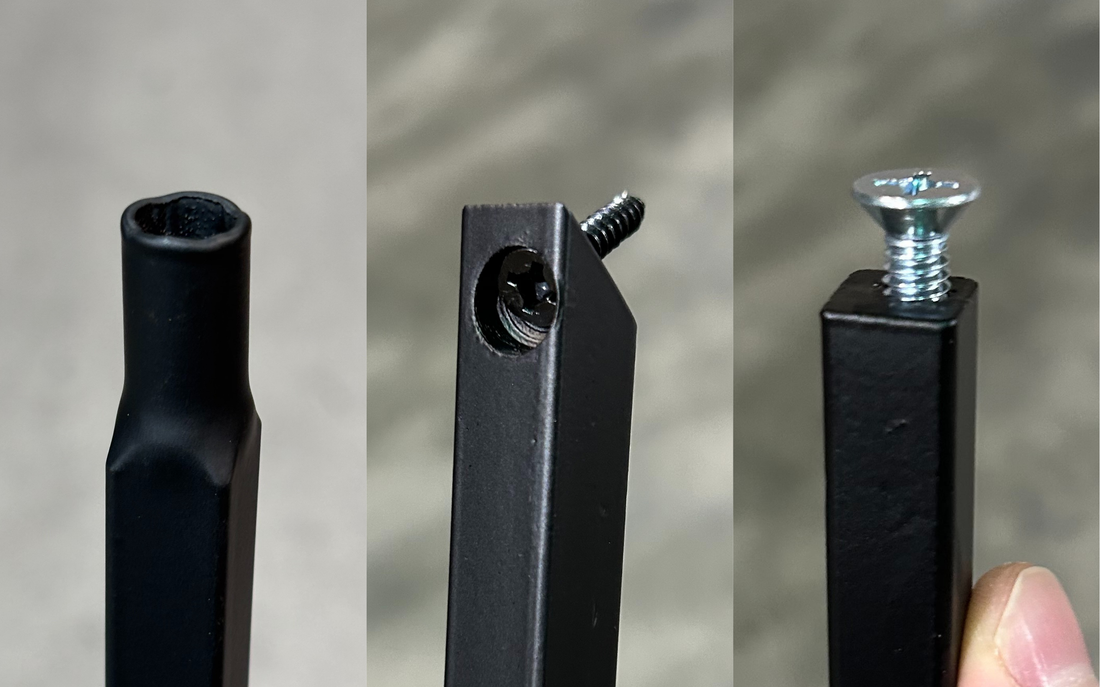

Pintop Installation – For Hollow Balusters Without Metal Insert

This method is used exclusively with hollow balusters that have no internal metal insert. The bottom of the baluster is a round pintop, which is inserted into a round hole drilled into the stair tread and secured with epoxy and/or screw. The top is square and typically fastened with a screw and/or epoxy into the underside of the handrail. The screws are used to wedge or pinch the baluster tightly into the hole.

The biggest advantage of this approach is simplicity. It’s lightweight, easy to cut, and quick to install—making it ideal for homeowners or installers handling decorative railing upgrades. The epoxy and screws provides the main hold, and shoes do not need to be added to the bottom resulting in a cleaner look.

However, this method is prone to loosening and rattling over time. Epoxy at the top can weaken from vibration, wear, or people pulling on the handrail. The hollow baluster’s limited surface area doesn’t bond well with epoxy, and the screw may damage the thin walls or eventually loosen.

This method is best for low-traffic areas or cosmetic installs where strength is less critical and ease of cutting is a priority.

Countersunk Thru-Hole – For Solid Balusters or Hollow with Metal Insert

This installation method is designed for solid balusters or hollow balusters with a metal insert.

Solid Balusters with Countersunk Thru-Hole: These are solid balusters that have been drilled and countersunk at the top of the baluster.

Hollow Balusters with Metal Insert With Countersunk Thru-Hole: These are hollow balusters that have a metal bar inserted and welded at the top of the baluster. The metal insert is then drilled and countersunk at the top of the baluster.

At the top, the baluster features a countersunk thru-hole. A screw passes through this hole into the underside of the handrail, locking the baluster in place from both ends. The countersunk allows the screw to sit flush, secure and hidden. The square bottom is inserted into a square hole on the tread and secured with epoxy.

This approach offers a strong, quiet, and durable install. The square shape at the bottom provides excellent surface contact, and because the epoxy is under compression (rather than tension), the grip is more reliable. The top screw keeps the baluster from shifting under pressure or movement.

This method, is ideal for staircases with moderate to heavy use, or for homeowners who want a secure and long lasting finish.

Threaded Hole Installation – For Solid Balusters or Hollow with Metal Insert

This installation method is also designed for solid balusters or hollow balusters with a metal insert.

Solid Balusters with Threaded Holes: The top of the solid baluster is drilled and tapped to create internal threads to accept a screw.

Hollow Balusters with Threaded Holes: These are hollow balusters that have a metal bar inserted and welded at the top of the baluster. The metal insert is then drilled and tapped to create internal threads to accept a screw.

The top of the baluster has a threaded hole that is used to fasten to a metal bar that sits under the wooden handrail. The square bottom is inserted into a square hole on the tread and secured with epoxy.

Threaded hole installs deliver the cleanest appearance—no visible fasteners—and the most secure hold.

This installation is ideal for stair remodels where a metal bar is already mounted beneath the wooden handrail, making replacement straightforward and similar to the original setup.

Conclusion

If you're looking for a quick, lightweight solution, hollow balusters without metal inserts offer simplicity—but with trade-offs in strength, stability and longevity. For the best quality and most secure install, the countersunk thru-hole method or threaded hole installs will be the cleanest and best option, especially when used with solid or hollow metal-insert balusters.