Choosing Between Solid and Hollow Iron Balusters

When renovating your staircase, selecting the right iron balusters significantly impacts durability and the quality of your staircase. This guide explores the key differences between solid and hollow iron balusters to help you make an informed decision for your home renovation project.

Understanding Iron Stair Baluster Basics

Iron spindles form the vertical components of your staircase railing system, providing both safety and style. Before making a selection, it's important to understand the fundamental differences between the two main types available on the market.

Premium Option: Solid Iron Balusters

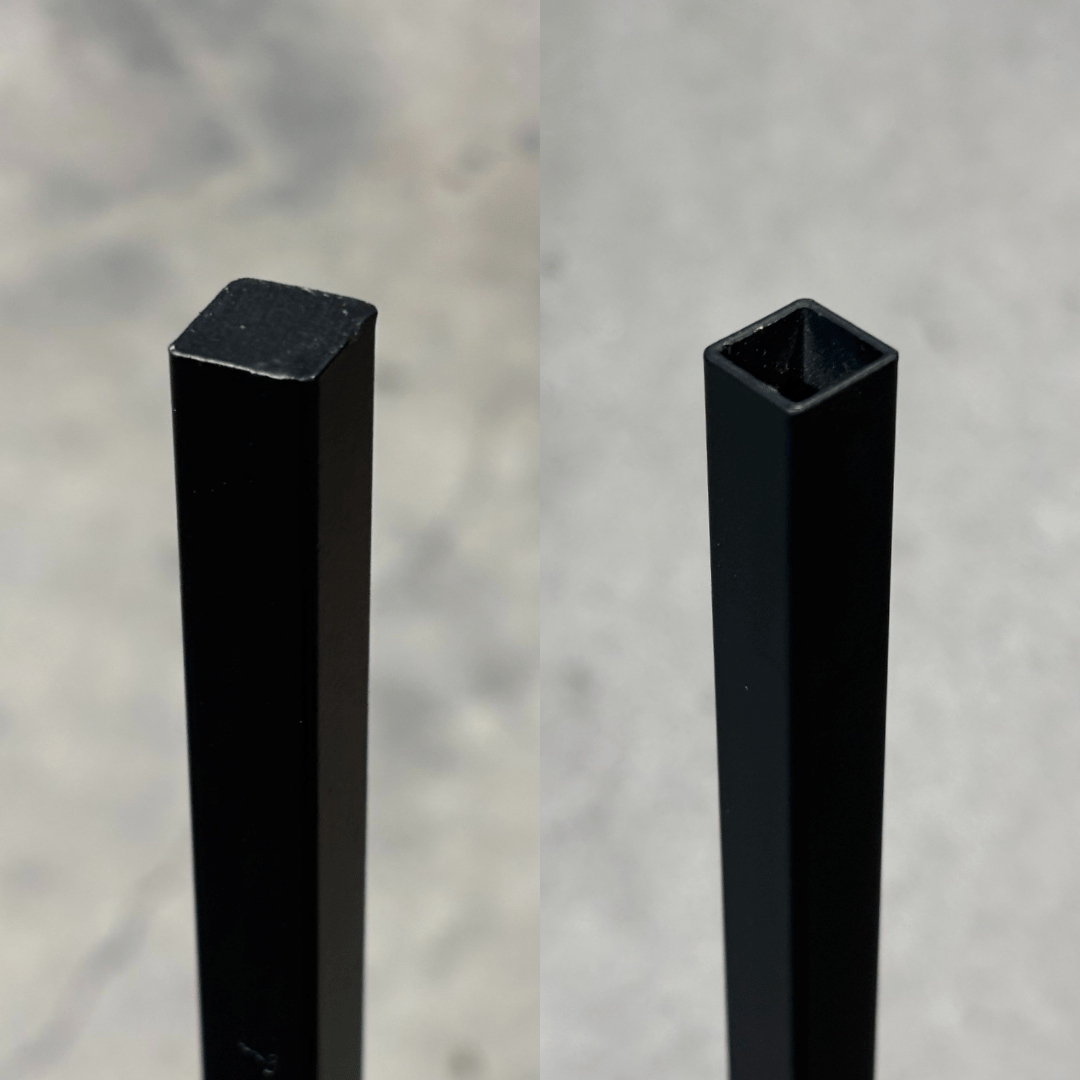

Solid iron balusters are completely solid throughout their entire length. This design provides increased strength and stability, making them particularly suitable for high-traffic areas.

Though they represent a higher initial investment, solid balusters typically deliver excellent longevity and maintain their appearance over extended periods, potentially enhancing your home's value.

They’re highly resistant to damage or impact over the lifetime of your staircase, making baluster replacements less likely. Solid balusters, if installed correctly, have the ability to pass most, if not all, local building codes in the US and Canada due to their high strength.

Due to their weight and solid core, solid balusters are more expensive to ship and harder to cut and modify.

Homeowners may want to drill their balusters directly into their wooden handrail or to install into a metal bar that sits directly under the wooden handrail. For these install methods, solid balusters are very suitable.

Cheaper Alternative: Hollow Iron Balusters

Hollow iron balusters feature a hollow interior. This construction significantly reduces the weight. The wall thickness of the hollow balusters significantly impacts the strength and whether or not it can pass local building codes.

Building codes for balusters are primarily intended to prevent people—especially children—from falling through or beneath the railing due to excessive spacing or structural failure. In the U.S., codes require balusters to withstand at least 50 pounds of horizontal force applied over a 12" x 12" area. This simulates a distributed load, such as someone leaning against the railing with their body or hands.

In Canada, the standard is more concentrated: each baluster or infill must resist a focused load of at least 112 pounds applied to a small area. This accounts for real-world scenarios like someone tripping and hitting a single baluster, a child kicking it, or furniture bumping into it during a move.

The lighter materials make handling and installation considerably easier and shipping is much cheaper. Hollow balusters often feature more intricate decorative patterns due to their more workable nature.

For budget-conscious homeowners, hollow balusters can offer cost savings for material costs and shipping costs while still providing the elegant appearance of wrought iron.

One consideration with hollow balusters is the potential for noise or rattling, especially if they are not secured properly. Because the metal is thinner, any looseness in the installation can result in movement or vibration over time. Pin top balusters, which are often secured with epoxy to the handrail, is susceptible to this.

To install a hollow balusters more securely, homeowners can drill their balusters directly into their wooden handrail or to install into a metal bar that sits directly under the wooden handrail. For these install methods, hollow balusters can be modified with metal inserts that have these holes.

Comparative Analysis

| Feature | Solid Iron Balusters | Hollow Iron Balusters |

| Strength & Durability |

|

|

|

Impact Resistance |

|

|

| Noise / Rattling |

|

|

| Installation Difficulty |

|

|

| Shipping Cost |

|

|

| Decorative Detail |

|

|

| Material Cost |

|

|

| Best For |

|

|

Making Your Final Selection

Whether you prioritize the quality of solid spindles or the economical benefits of hollow alternatives, your decision should align with your specific home requirements. Many homeowners today are looking for modern, contemporary baluster designs, which both solid and hollow balusters are available to suit this style.